Diffusion Coating

Diffusion coating is used for improving abrasion and heat resistance as well as friction properties of the steel parts.

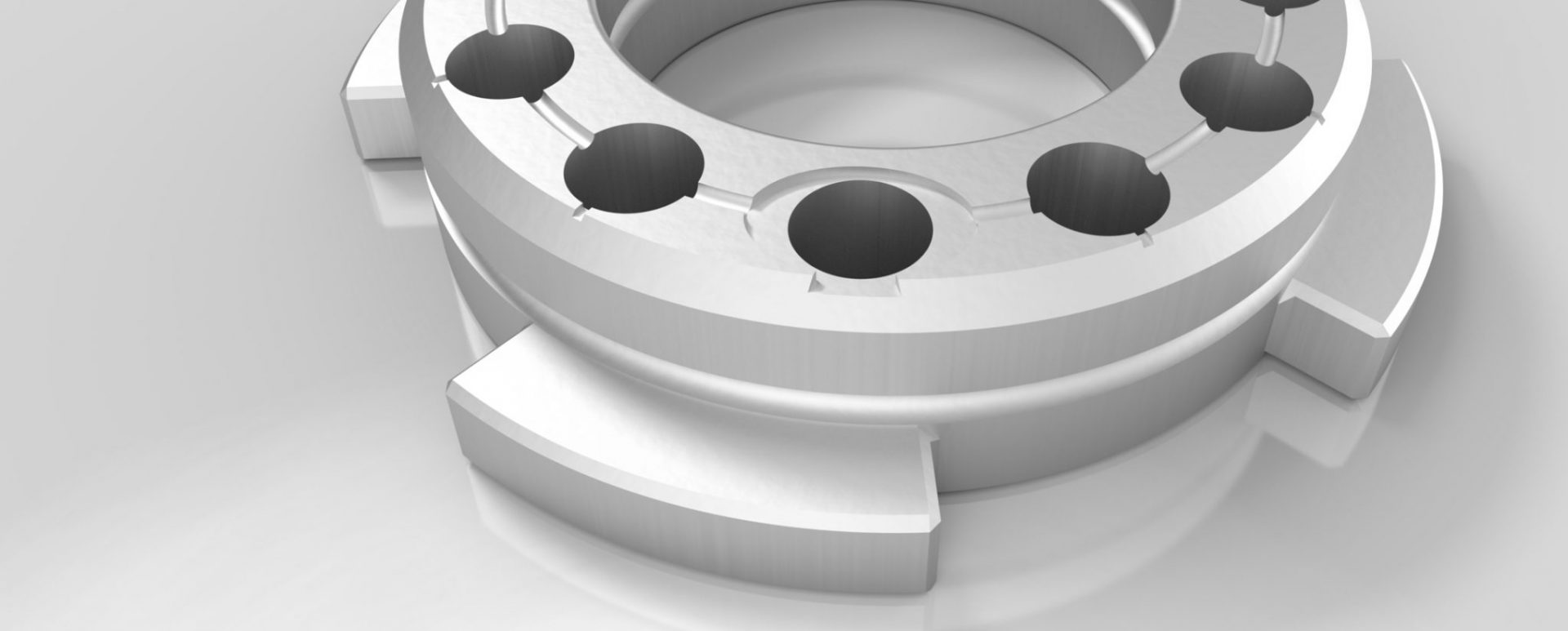

DiffusionCoat coatings can be used for coating of metal, for sliding and wear surfaces of machine components and tools, for torque transmission mechanisms and for molds. In the process industry it can be used for glide bearings, nozzles, valves, spindles, pumps, protective tubes and sieve plates.

It is also possible to coat the internal surface of small holes.

Diffusion coating improves the wear resistance of steel

One of the most important features of the surfaces of metal, in addition to abrasion resistance, is adhesion. The diffusion method used by Fincoat works by using the hard surface layer forming elements to penetrate the surface of the metal at a high temperature inwardly, forming a variety of ceramic compounds. The principle is similar to the conventional case in hardening of steel, but in addition, the diffusion method includes special additives such as boron, vanadium, niobium and others that provides multiple increases in surface hardness.

CVD-coating is a method used for titanium carbide coatings.