Mining industry

Durable and cost-effective coating solutions for the challenges of the mining industry

A reliable partner for the mining industry

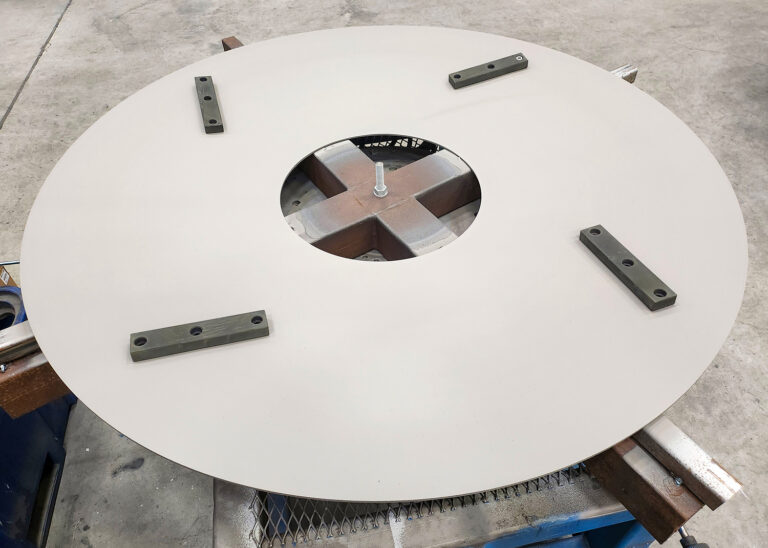

Equipment and components are put to the real test in the demanding production conditions of the mining industry. The equipment is often large and needs to operate reliably under aggressive corrosive conditions and high temperatures. We help to extend the service life of your machinery with cost-effective and durable coating solutions that protect equipment from deposits, wear and corrosion.

We help to extend the service life of components already in use, but we also act as a product development partner for new production. Most of our coatings can be flexibly delivered as an on-site service.

Our solution

Cleanliness

Improved corrosion resistance

Improved corrosion resistance

Coating solutions against corrosion caused by moisture, chemicals and pollutants.

Read more

Improved wear resistance

Improved wear resistance

Coating solutions to slow component wear and extend component service life.

Read more

Customer service

Customer service

Not sure which coating solution would be right for your needs and production environment? Don't worry! Let our experts solve your challenges for you.

Read more

Customer service

Not sure which coating solution would be right for your production environment? Don’t worry, our experts are here to help!

Tailor-made coating solutions for your needs

Our experts have strong technical competence and understanding of the demanding conditions in the mining industry. However, it’s important for us to know the specific characteristics of your production environment so that we can provide the right solution for your business. We will study your production environment in detail and tailor a coating solution to meet your needs.

We always use the latest technology and high-quality coating materials, which we constantly develop with our partners. Our methods include thermal spraying, polymer coating and diffusion coating.

Methods and products

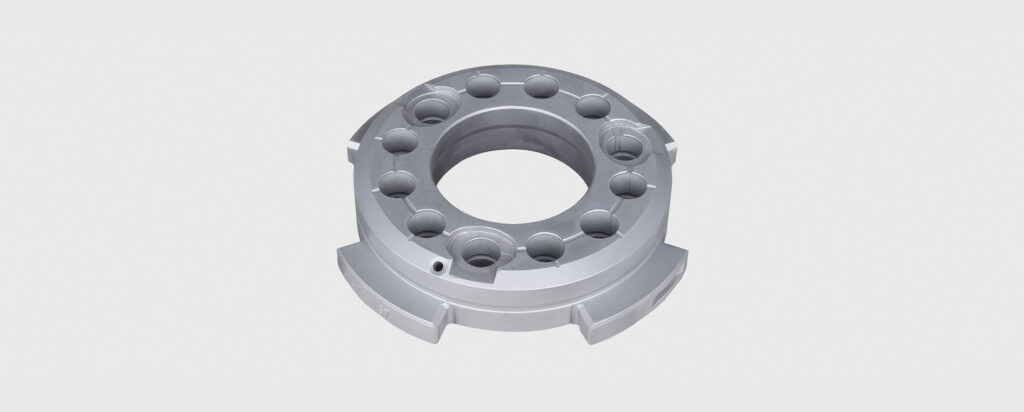

DiffusionCoat

Diffusion coating improves the wear resistance of steel parts. The coating technology enables the coating of multi-dimensional shapes and objects. The advantages of diffusion coating are most evident on surfaces where precision and maintaining resistance is critical.

With regard to diffusion coating, we offer the following coating solutions for different grades of steel:

• Boriding for all grades of steel

• Vanadium carbide for steel with low carbon content

• Titanium carbide for tool steel

• Diffusion aluminium coating for stainless and refractory steel

SuperStrong

The innovative SuperStrong range of coatings is suitable for new, more demanding applications in addition to conventional hard coating applications, opening up new possibilities for a whole new range of applications. SuperStrong products achieve significantly better coating quality and mechanical properties compared to conventional hard coating solutions.

NonStickCoat

NonStickCoat is an easy-to-clean thin-film coating that enhances cleanliness in various contact-free process surfaces.

CleanCoat T

CleanCoat T is a coating that provides better cleanliness, corrosion resistance and abrasion resistance with either a single or double-layer structure. The structure consists of the hard coating base combined with the latest nano-tech materials or, when more suitable, only the nano-tech coating.

International and responsible operator

We are a global company, driven by customer focus, reliability and quality. We have been awarded the OHSAS 18001, ISO 9001 and ISO 14001 quality certificates.

Our customers