Forest industry

Durable and cost-effective hard coating solutions for the challenges of the forest industry

Coating partner for the forest industry

We help you to extend the service life of your machinery with durable and cost-effective coating solutions that help minimise production downtime. We solve the most common challenges of the forest industry, such as accumulations, and chemical, soot and resin deposits, as well as corrosion and wear.

We operate as a product development partner and help to extend the service life of the components in use. Most of our coatings can be flexibly carried out as an on-site service without unnecessary production downtime.

Our solution

Cleanliness

Improved corrosion resistance

Improved corrosion resistance

Coating solutions against corrosion caused by moisture, chemicals and pollutants.

Read more

Improved wear resistance

Improved wear resistance

Coating solutions to slow component wear and extend component service life.

Read more

Customer service

Customer service

Not sure which coating solution would be right for your needs and production environment? Don't worry! Let our experts solve your challenges for you.

Read more

Customer service

Not sure which coating solution would be right for your production environment? Don’t worry, our experts are here to help!

Tailor-made coating solutions for your needs

Our experts have strong technical competence and understanding of the challenges and needs of forest industry production. However, it’s important for us to know the specific characteristics of your production environment so that we can provide the right solution for you. We will study your production processes in detail and tailor a coating solution to meet your needs.

We always use the latest technology and high-quality coating materials, which we constantly develop with our partners. Our methods include thermal spraying and grinding.

On-site coating to help the forest industry

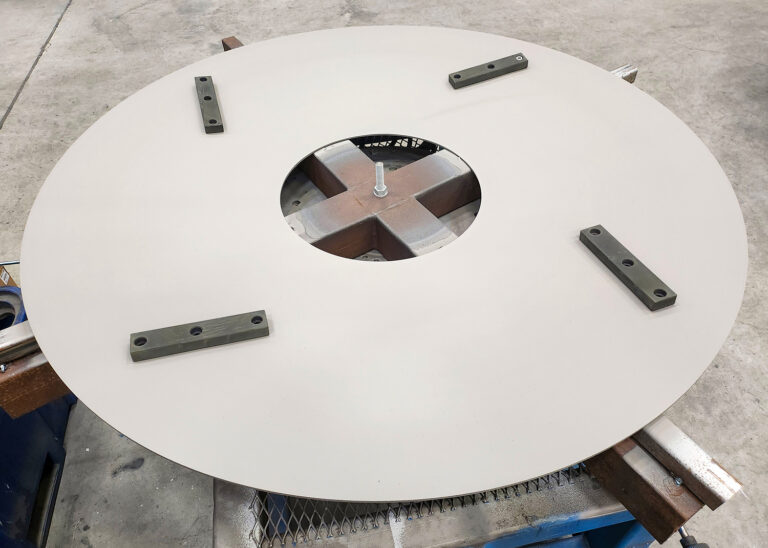

Thermal spraying provides excellent tools for coating different surfaces with flexibility. It also allows large process industry equipment and components to be coated as an on-site service, minimising downtime and overall costs. Reduced need for maintenance, longer service life, less friction and lighter structures mean more reliable equipment and lower operating costs for your business.

Methods and products

SlipStop

SlipStop is an abrasion-resistant, profile-retaining, high-strength, hard metal coating that is well suited for applications such as carrier rollers and reeling drums. The high hardness of the coating ensures long service life and wear resistance with different surface thicknesses according to the application requirements.

SuperStrong

The innovative SuperStrong range of coatings is suitable for new, more demanding applications in addition to conventional hard coating applications, opening up new possibilities for a whole new range of applications. SuperStrong products achieve significantly better coating quality and mechanical properties compared to conventional hard coating solutions.

Dryer Roll Cover DOH

The Dryer Roll Cover DOH coating improves in particular the peeling and cleanliness properties of the dryer cylinder surface. These features improve the drying capacity of the cylinder and save the energy used for drying purposes. The coating also provides protection against wear and corrosion in paper and cardboard machine environments. The advantage of the DOH coating is that it can be quickly prepared even in on-site conditions without the need for external heating.

VacRollCoat

VacRollCoat is a chemical corrosion-resistant multi-layer coating for VAC cylinders, developed in collaboration with research institutes and the chemical industry. The coating thickness is always tailored to the customer’s requirements and circumstances. The coating helps to restore the cylinder surface to a condition as good as new, bringing the service lives of dryer fabrics to normal levels and eliminating quality problems caused by corrosion.

NonStickCoat

NonStickCoat is an easy-to-clean thin-film coating that enhances cleanliness in various contact-free process surfaces.

CleanCoat T

CleanCoat T is a coating that provides better cleanliness, corrosion resistance and abrasion resistance with either a single or double-layer structure. The structure consists of the hard coating base combined with the latest nano-tech materials or, when more suitable, only the nano-tech coating.

International and responsible operator

We are a global company, driven by customer focus, reliability and quality. We have been awarded the OHSAS 18001, ISO 9001 and ISO 14001 quality certificates.

Our customers