Mechanical and equipment engineering

Durable and cost-effective coating solutions for the challenges of mechanical and equipment engineering

Product development partner for mechanical and equipment engineers

We partner with mechanical and equipment engineers to help them to improve the overall efficiency of their manufacturing process, beginning with the product development stage. We help you to increase the cost efficiency and environmental friendliness of production by allowing you to build equipment with lighter, durable coated components. Our modern coating and material solutions also help you to extend the service life of your equipment.

Common coating applications include sleeves, shafts and hydraulic cylinders, but our in-depth material competence allows us to tailor coating solutions for a wider range of applications. We also help to extend the service life of components already in use. In addition to coating, we provide parts through our subcontracting network.

Our solution

Cleanliness

Improved corrosion resistance

Improved corrosion resistance

Coating solutions against corrosion caused by moisture, chemicals and pollutants.

Read more

Improved wear resistance

Improved wear resistance

Coating solutions to slow component wear and extend component service life.

Read more

Customer service

Customer service

Not sure which coating solution would be right for your needs and production environment? Don't worry! Let our experts solve your challenges for you.

Read more

Customer service

Not sure which coating solution would be right for your production environment? Don’t worry, our experts are here to help!

Tailor-made coating solutions for your needs

Our experts have strong technical competence and an understanding of how to improve the efficiency of manufacturing processes in the mechanical and equipment engineering industry. However, it’s important for us to know the specific characteristics of your production environment so that we can provide the right solution for your business. We will study your production processes in detail and tailor a coating solution to meet your needs.

We always use the latest technology and high-quality coating materials, which we constantly develop with our partners. Our methods include thermal spraying, diffusion coating and grinding.

Methods and products

We use a variety of coating and grinding technologies and combinations of both.

Grinding

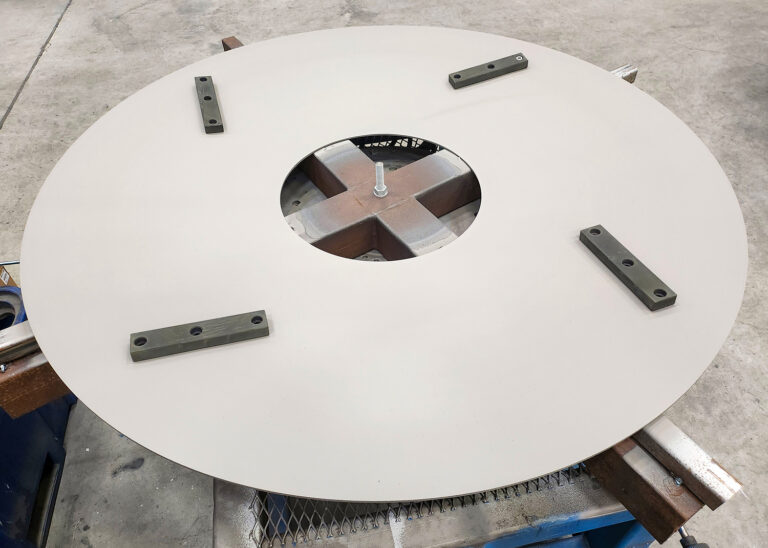

Grinding restores the dimensional tolerances of worn surfaces and, at the same time, restores the surface quality to the required level. We have the expertise and experience and versatile equipment to carry out grinding also at the customer’s premises. Examples of typical objects that can be grinded include dryer cylinders, VAC cylinders, roller cylinders, Clupak cylinders, Yankee cylinders and MG cylinders, as well as support rings and sealing surfaces.

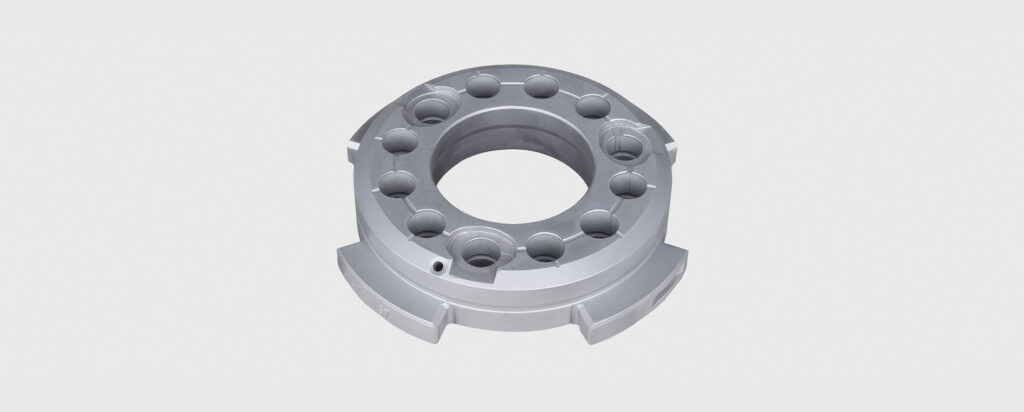

DiffusionCoat

Diffusion coating improves the wear resistance of steel parts. The coating technology enables the coating of multi-dimensional shapes and objects. The advantages of diffusion coating are most evident on surfaces where precision and maintaining resistance is critical.

With regard to diffusion coating, we offer the following coating solutions for different grades of steel:

• Boriding for all grades of steel

• Vanadium carbide for steel with low carbon content

• Titanium carbide for tool steel

• Diffusion aluminium coating for stainless and refractory steel

Thermal spraying

Thermal spraying is a versatile coating method that improves the surface properties of parts, protecting machines from friction, wear, corrosion, and dirt. Thermal spraying also allows parts to be coated on site, minimizing downtime and overall costs.

All metallic materials, as well as aluminum, brass, and copper, are suitable as base materials. Thermal spraying is suitable for bushings, shafts, valve parts, cylinders, hydraulic cylinders, and other wear-prone machine parts.

Thermal spraying is carried out in automated robot cells, where the shape of the workpiece does not impose any restrictions. Workpieces of all shapes can be processed, and we always help to find a solution even in special cases.

Washing and cleaning

Before coating, the surface to be treated must be completely clean to ensure proper adhesion and durability of the coating. Cleaning ensures the long service life and functionality of the coating. The washing method used is chosen on a case-by-case basis, using a variety of acid and alkaline washes as required.

International and responsible operator

We are a global company, driven by customer focus, reliability and quality. We have been awarded the OHSAS 18001, ISO 9001 and ISO 14001 quality certificates.

Our customers