Improved wear resistance

Our coating solutions help to slow down wear and tear on equipment and components in a variety of environments.

Hard coatings to prevent wear

Equipment and components are put to the test at different stages of production. Wear cannot be completely prevented, but it can be significantly slowed down. We help to extend the service life of your equipment by protecting it from wear.

We offer durable and cost-effective coating solutions for both new production and existing components. Most of our coatings can be flexibly delivered as an on-site service.

Advantages

Reliability

Coating extends the service life of components and prevents production downtime due to worn parts.

Efficiency

Coating helps to extend the service intervals of equipment, minimising the time spent on maintenance.

Cost savings

o Coating allows the use of cheaper base materials, as only the surfaces that are prone to wear need to be coated.

Environmental friendliness

The service life of components can be extended significantly, reducing the need to replace them.

Tailor-made coating solutions for your needs

It is important for us to understand the challenges related to your environment so that we can provide the right solution for your needs. We will carefully study your production environment and create a custom coating solution based on our advanced products to meet your business needs.

We always use the latest technology and high-quality coating materials, which we constantly develop with our partners. Our methods include thermal spraying and diffusion coating.

Pinnoituksessa hyödynnämme aina uusinta teknologiaa ja laadukkaita pinnoitemateriaaleja, joita kehitämme jatkuvasti yhteistyökumppaneidemme kanssa. Menetelminä käytämme termistä ruiskutusta ja diffuusiopinnoitusta.

Our methods

Thermal spraying

Thermal spraying is a versatile coating process that improves the surface properties of parts, protecting machines from friction, wear, corrosion and dirt. Thermal spraying also allows the coating of surfaces on site, minimising downtime and overall costs.

All metallic materials are suitable as a base material, as well as aluminium, brass and copper. Thermal spraying is suitable for applications such as sleeves, shafts, valve parts, cylinders, hydraulic cylinders and other wear parts.

Thermal spraying is carried out in automated robotic cells, where the shape of the surface does not impose any restrictions. Surfaces of all shapes can be coated, and we will always help you find a solution, even in special cases.

Diffusion coating

Diffusion coating is mainly suitable for steel materials; it improves the friction properties of steel parts and their resistance to wear and heat. Diffusion coating can be used on sliding and wearing surfaces of machine parts and tools, in power transmission and various moulds. In the process industry, its common applications include shaft sleeves, nozzles, valves, spindles, pumps, casing pipes and sieve plates. It is also possible to coat small internal holes with the coating.

The methods include boriding, diffusion aluminium coating and chemical vapor deposition (CVD). We help you to choose the right method depending on the application.

Our products

SlipStop

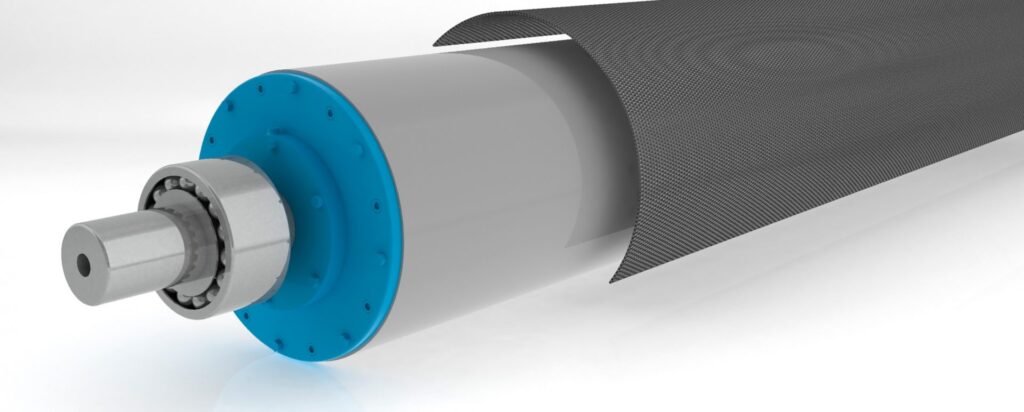

SlipStop is an abrasion-resistant, profile-retaining, high-strength, hard metal coating that is well suited for applications such as carrier rollers and reeling drums. The high hardness of the coating ensures long service life and wear resistance with different surface thicknesses according to the application requirements.

DiffusionCoat

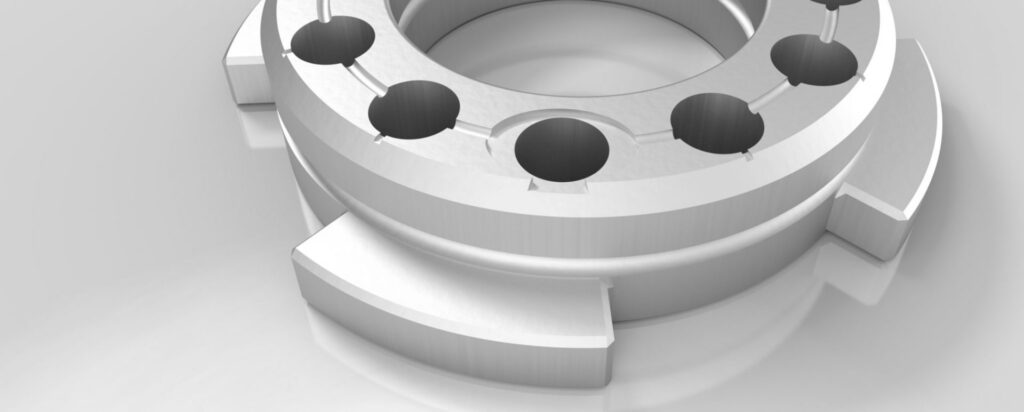

Diffusion coating improves the wear resistance of steel parts. The coating technology enables the coating of multi-dimensional shapes and objects. The advantages of diffusion coating are most evident on surfaces where precision and maintaining resistance is critical.

With regard to diffusion coating, we offer the following coating solutions for different grades of steel:

• Boriding for all grades of steel

• Vanadium carbide for steel with low carbon content

• Titanium carbide for tool steel

• Diffusion aluminium coating for stainless and refractory steel

SuperStrong

The innovative SuperStrong range of coatings is suitable for new, more demanding applications in addition to conventional hard coating applications, opening up new possibilities for a whole new range of applications. SuperStrong products achieve significantly better coating quality and mechanical properties compared to conventional hard coating solutions.

BoilerCoat

BoilerCoat coatings are particularly suitable for high-temperature applications to prevent erosion and corrosion. The ideal coating material for BoilerCoat is determined according to the operating environment.