Improved corrosion resistance

Our coating solutions help to protect equipment from moisture, chemicals and other corrosive conditions.

Hard coatings to prevent corrosion

Corrosion is a common problem in many environments where machinery is exposed to moisture, chemicals and other corrosive conditions.

Corrosion cannot be completely prevented, but the corrosion resistance of equipment and components can be improved. We help you to extend the service life of your equipment by protecting it from corrosion damage.

We offer durable and cost-effective coating solutions for both new production and existing components. Most of our coatings can be flexibly delivered as an on-site service.

Advantages of coating

Reliability

Coating extends the service life of components and minimises production downtime due to worn parts.

Efficiency

Coating helps to extend the service intervals of equipment, minimising the time spent on maintenance.

Environmental friendliness

The service life of components can be extended significantly, reducing the need to replace them.

Tailor-made coating solutions for your needs

It is important for us to understand the challenges of your production environment so that we can provide the right solution for your needs. We will carefully study your production environment and create a custom coating solution based on our advanced products to meet your business needs.

We always use the latest technology and high-quality coating materials, which we constantly develop with our partners. Our methods include thermal spraying and polymer coating.

Our methods

Washing and cleaning

Before coating, the surface to be treated must be completely clean to ensure proper adhesion and durability of the coating. Cleaning ensures the long service life and functionality of the coating. The washing method used is chosen on a case-by-case basis, using a variety of acid and alkaline washes as required.

Grinding

Grinding ensures the desired surface quality and accuracy. We are also able to grind bodies of revolution on site at the customer’s premises. Grinding can be carried out for the purposes of cleaning and shaping, both in our factory and as an on-site service. Possible objects to be grinded include lead, carrier and calender rolls, drying and VAC cylinders, Clupak rolls, Yankee and MG cylinders. We produce precision grinding services with our partners. Surfaces of all shapes can be coated, and we will always help you find a solution, even in special cases.

Thermal spraying

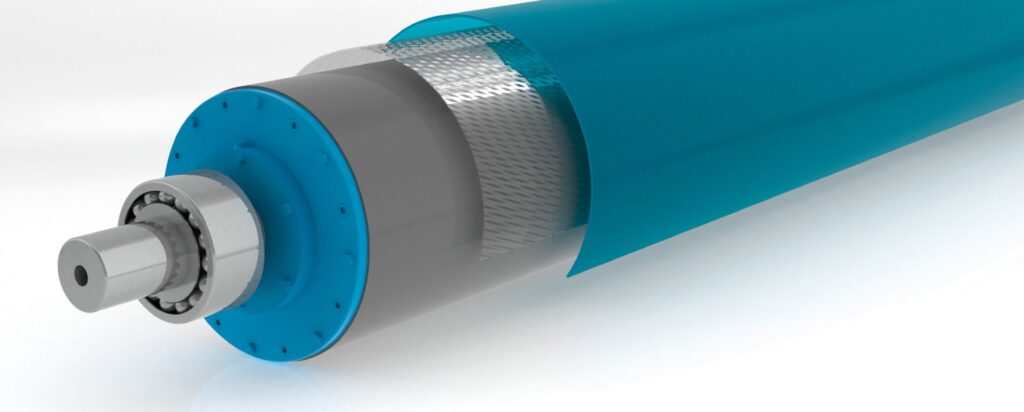

Thermal spraying is a versatile coating process that improves the surface properties of parts, protecting machines from friction, wear, corrosion and dirt. Thermal spraying also allows the coating of surfaces on site, minimising downtime and overall costs.

All metallic materials are suitable as a base material, as well as aluminium, brass and copper. Thermal spraying is suitable for applications such as sleeves, shafts, valve parts, cylinders, hydraulic cylinders and other wear parts.

Thermal spraying is carried out in automated robotic cells, where the shape of the surface does not impose any restrictions. Surfaces of all shapes can be coated, and we will always help you find a solution, even in special cases.

Our products

SuperStrong

The innovative SuperStrong range of coatings is suitable for new, more demanding applications in addition to conventional hard coating applications, opening up new possibilities for a whole new range of applications. SuperStrong products achieve significantly better coating quality and mechanical properties compared to conventional hard coating solutions.

Dryer Roll Cover DOH

The Dryer Roll Cover DOH coating improves in particular the peeling and cleanliness properties of the dryer cylinder surface. These features improve the drying capacity of the cylinder and save the energy used for drying purposes. The coating also provides protection against wear and corrosion in paper and cardboard machine environments. The advantage of the DOH coating is that it can be quickly prepared even in on-site conditions without the need for external heating.

BoilerCoat

BoilerCoat coatings are particularly suitable for high-temperature applications to prevent erosion and corrosion. The ideal coating material for BoilerCoat is determined according to the operating environment.

VacRollCoat

VacRollCoat is a chemical corrosion-resistant multi-layer coating for VAC cylinders, developed in collaboration with research institutes and the chemical industry. The coating thickness is always tailored to the customer’s requirements and circumstances. The coating helps to restore the cylinder surface to a condition as good as new, bringing the service lives of dryer fabrics to normal levels and eliminating quality problems caused by corrosion.

CleanCoat T

CleanCoat T is a coating that provides better cleanliness, corrosion resistance and abrasion resistance with either a single or double-layer structure. The structure consists of the hard coating base combined with the latest nano-tech materials or, when more suitable, only the nano-tech coating.